Radiation & Shielding

Magnetic Shielding

Positioning applications, which use linear motors to move a part under an e-beam,

as for example in

scanning

electron microscope (SEM) or in E-Beam

Lithography, often require shielding of the exposed magnet channels. Mu Metal is

commonly used for that purpose. Typical linear motor Rare Earth

magnets have flux density of about 0.7 Tesla at the surface of the magnet.

Some of

this flux is captured by the linear motor magnet channels ( back iron ).

At about 100 mm away from the the channel the flux density diminishes

exponentially to the order of a few Gauss. A DC magnetic flux density

of a few gauss may disturb the e-beam process, which is typically specified to

be protected on order of a mGauss. The effect of a steady flux

may be mapped out. However, if the flux density changes its magnitude during process, such as in

a moving compounded XY linear stages, shielding

may be required.

Design of magnetic shield is an iterative process, which is best being done by

experienced experts. The following are references

to two magnetic shield supplies.

|

|

|

Mu Metal

http://mumetal.co.uk

|

Netic and Co-Netic materials

http://www.magnetic-shield.com/products/alloys.html

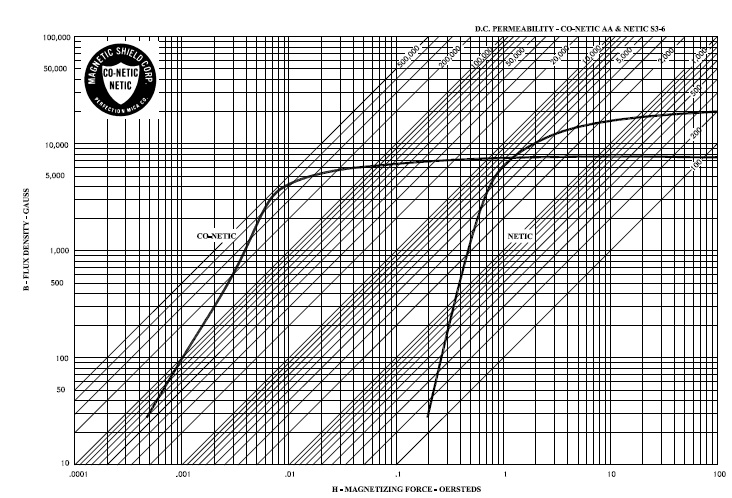

Our NETIC® and CO-NETIC® alloys, presented in this guide,

are proprietary materials developed by Magnetic Shield Corporation specifically

to provide effective magnetic shielding. Both are available in either foil or sheet form in a

convenient range of material thickness. The permeability

chart you see illustrates the unique properties of each material. In fields of low intensity,

CO-NETIC AA is used for its high initial permeability and

corresponding high attenuation characteristics. In fields of high intensity, NETIC S3-6 is

preferred because of its high magnetic saturation

characteristics. In some instances, combinations of the two materials may

be useful. NETIC material is always placed closest to the magnetic

field source. Many users explore the effects of magnetic shielding alloys

through use of our

Magnetic Shielding Lab Kit quickly prototyping

solutions to magnetic interference problems. The

sheet from these materials is preferred in areas of high magnetic force, where greater

alloy

thickness is necessary, or where substantial production tooling investment is justified.

Examples: Power supplies, CRTs, photomultiplier tubes, disk

drives, test chambers, and many electronic assemblies utilize cans, cylinders, boxes and

enclosures fabricated from flat sheet by heliarc or spot

welding. Foil may provide effective shieklding with minimum fabrication, avoiding expensive

tooling and extended production time. Examples:

Prototype and laboratory evaluation projects and production applications such as

shielding field-sensitive components, printed circuit boards,

instruments, signal leads and power cables.

|

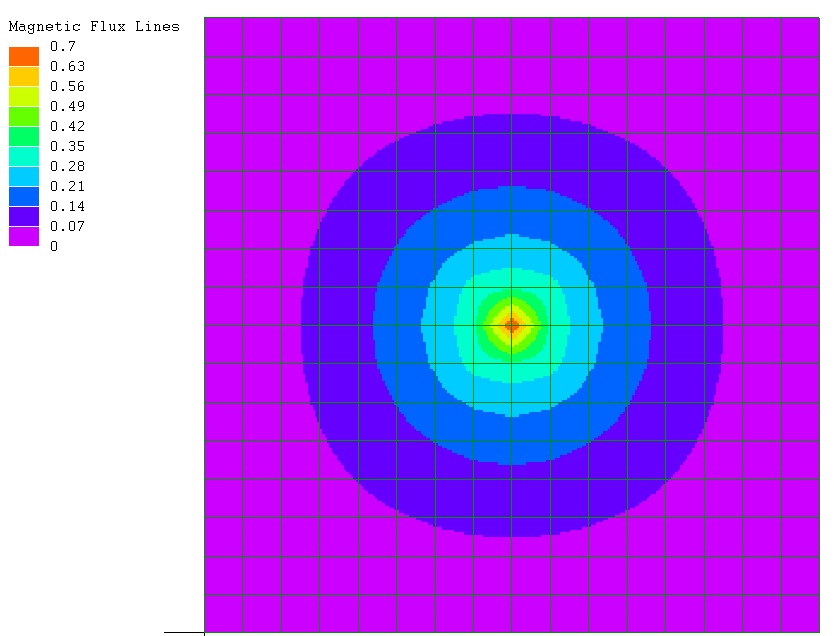

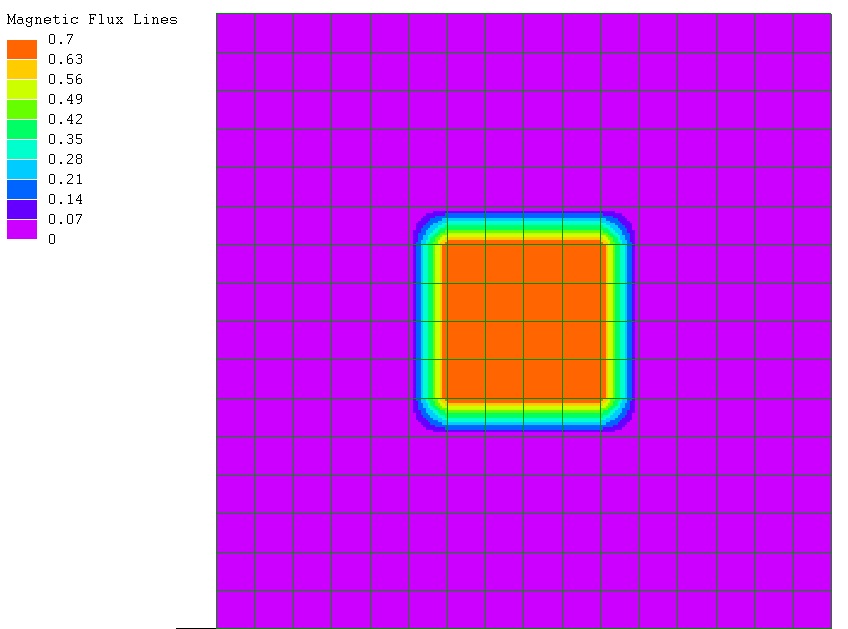

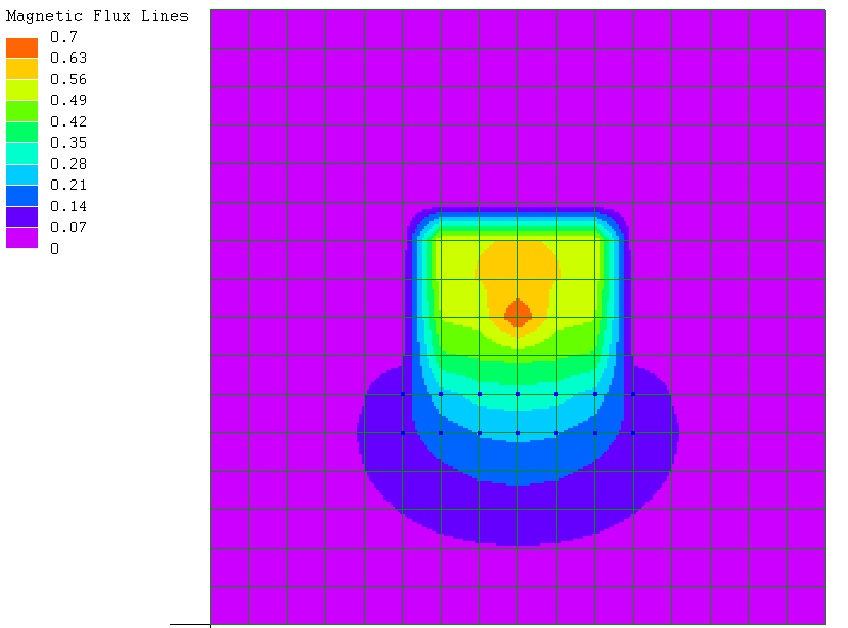

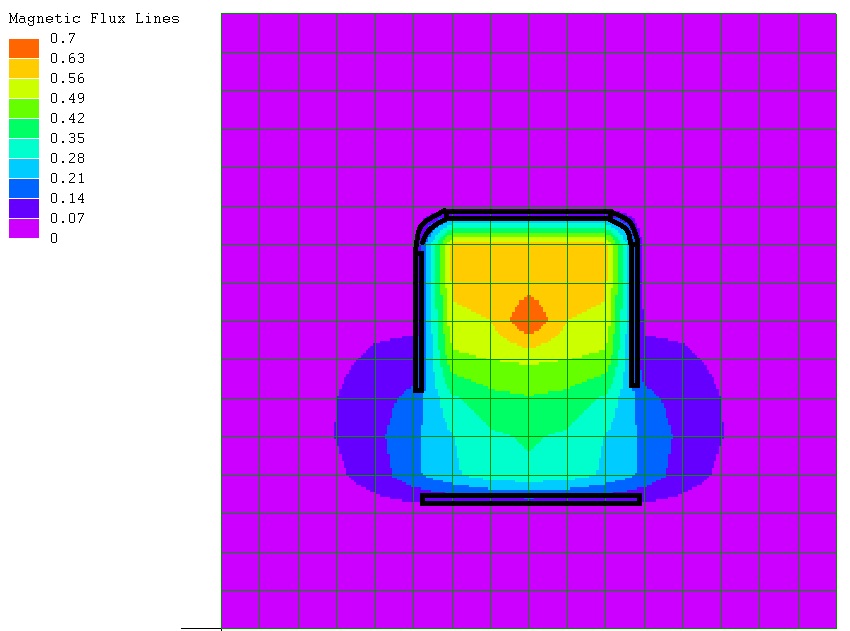

Mu Metal Shielding examples of 0.7 Tesla

magnetic source at

the ceneter of 400 x 400mm space ( Optinet analysis samples ) |

|

unshielded |

enclosed on four sides |

shielded on three sides

|

shielded on four sides with an opening |

|

|

EMI / RFI |

|

|

|

Design consideration for EMI / RFI shielding:

1. Separate signal cables from power cables

2. Consider linear servo amplifier ( rather than PWM ) in applications which

require very high smoothness of motion

3. Use common grounding ( including electrical cabinets, motors, encoders,

limits )

4. Use shielded cables

5. Use chokes

6. Use twised wires

7. Use metalized fabric outer surface for cables

8. Use ferrites

9. Transmit signals in differential form

10. Amplify signals to higher signal to noise ratio

11. Convert signal into currents for transmission

12. Convert signals to digital form

|

|

|

|

|

|

|

|

Ionizing Radiation |